TECHNICAL INFORMATION

READ RANGE

Read range for SH/08-100RF US using handheld readers 30 dBm (Range in meters):

X-Direction

Circular Extended Scanner: 10.3 meters

Linear Scanner: 7.7 meters

Y-Direction

Circular Extended Scanner: 8 meters

Linear Scanner: 6 meters

Z-Direction

Circular Extended Scanner: 11.3 meters

Linear Scanner: 8.3 meters

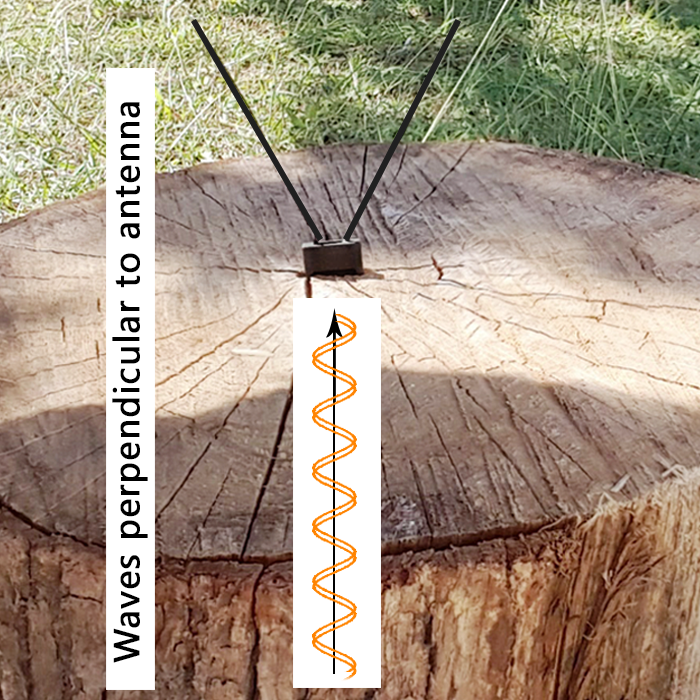

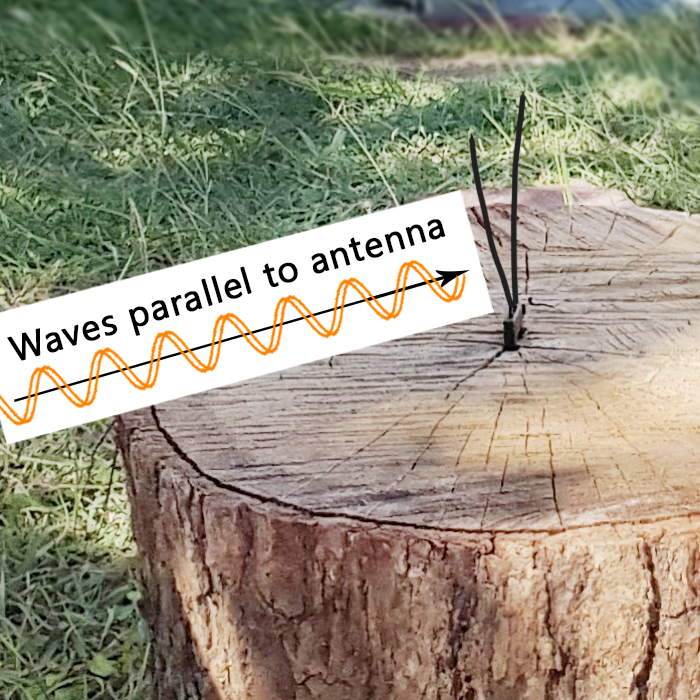

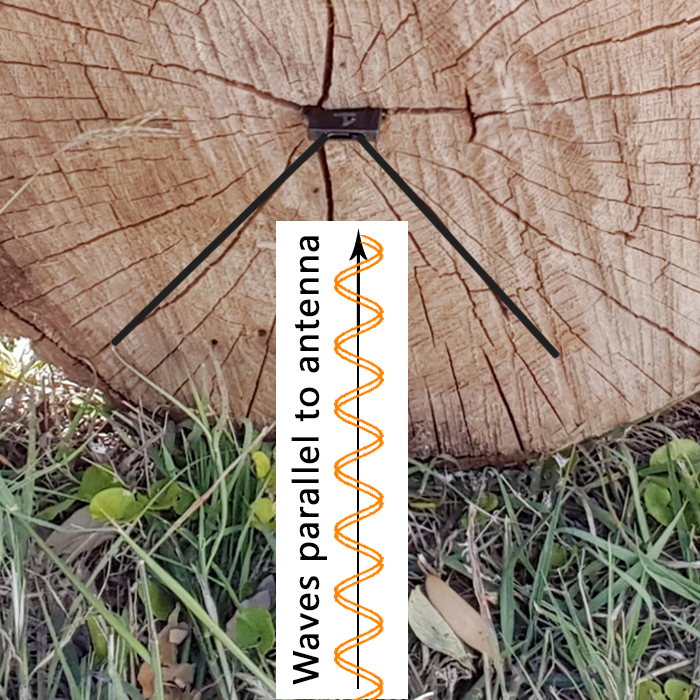

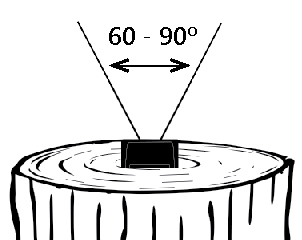

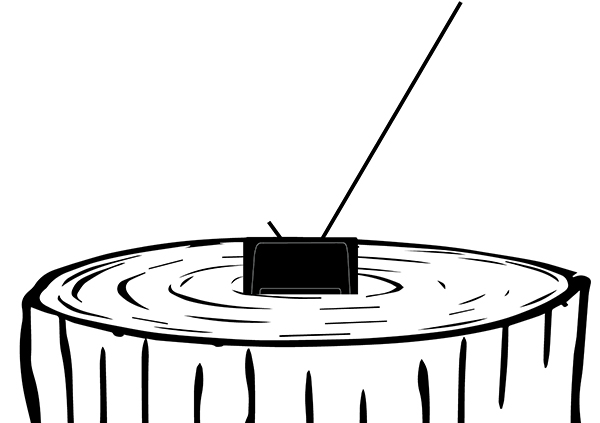

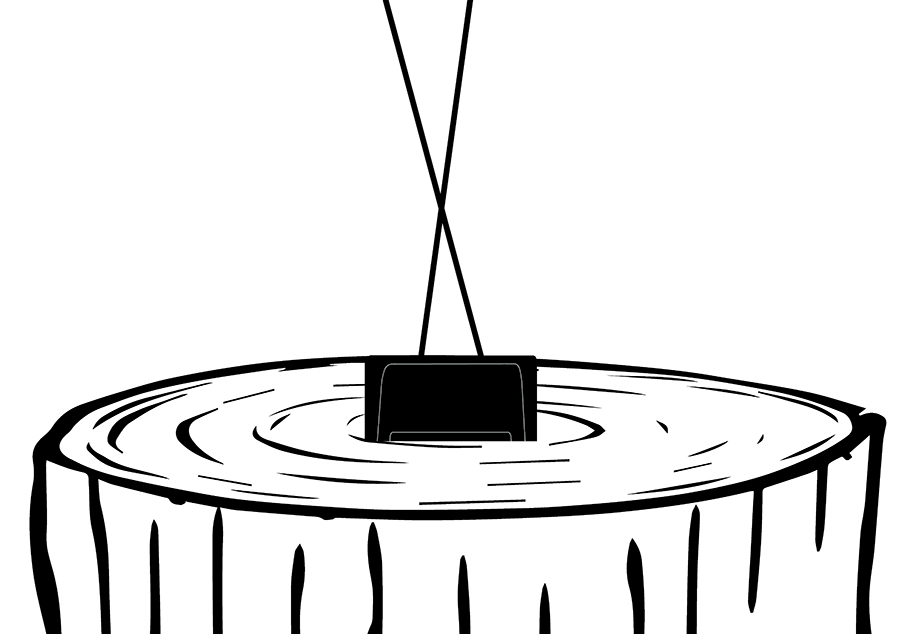

ANTENNAE POSITIONING

Ideal Positioning

If one antennae is cut off at the staple crown, the readability is still quite good.

If both antennae are cut off at the staple crown, the readability is about 9-10 inches.

If the antennae are crossed, the readability is dramatically reduced.

HIGH TEMPERATURE EXPOSURE

We found no measurable difference in readability before and after the following high temperature tests.

| Type of Test | Temperature | Duration |

|---|---|---|

| Oven | 250° | 24 hrs. |

| Oven | 400°F | 4 hrs. |

| Oven | 400°F | 10.5 hrs. |

| Oven | 415°F | 2 hrs. |

| Hot Water Submersion | 160°F | 100 hrs. |

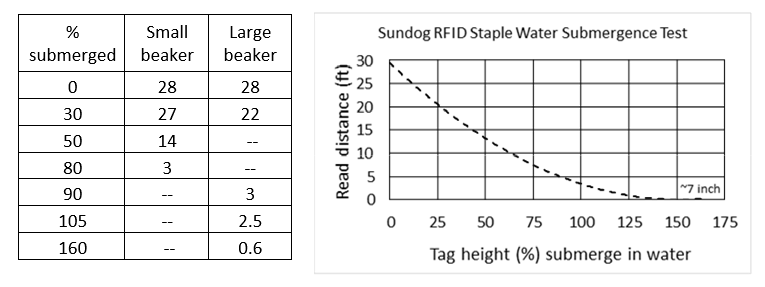

SUBMERSION READABILITY

Read distance tests on SUNDOG RFID tags were conducted with varying water volumes and submersion levels as shown below.

(% = submersion level)

The table below shows the X-direction read distance (see read direction information from READ RANGE section above) using a linear handheld reader. The large beaker data is also presented graphically. Surprisingly, when the tag and antenna are completely submerged, the SUNDOG RFID tag is still readable at 2.5 feet. Tests show that increasing depth of water reduces the read distance. While this experiment is noteworthy, it is expected that results will vary depending on the actual environment.

CREOSOTE PROCESS FOR UTILITY POLES AND RAILROAD TIES

SUNDOG® RFID tags were tested for readability before and after the creosote treating process for utility poles and railroad ties. SUNDOG® tags were installed on the ends of utility poles and successfully read at distances over 17 feet. Poles were then steamed at 240°F for 10 – 12 hours followed by a vacuum of 24 – 26 inches of Hg to pull the moisture from the wood. Next, the poles were covered in creosote and the pressure was repeatedly cycled between 25 psi and 150 psi for 3 – 4 hours to allow the preservative to penetrate. The tags on the poles were read the next day and all tags were successfully read after going through the creosote treating process.

We are currently running accelerated weathering tests. Check back for new tests data entries.